With increasing demand of having Predictive Maintenance for Connected Assets, KAISPE has introduced predictive maintenance functionality in its solutions. In this blog, we will briefly discuss how we have included predictive maintenance feature in our IoT web portal to help customers proactively maintain their business assets.

We provide Predictive Maintenance through Microsoft Azure Machine Learning in just a few easy steps.

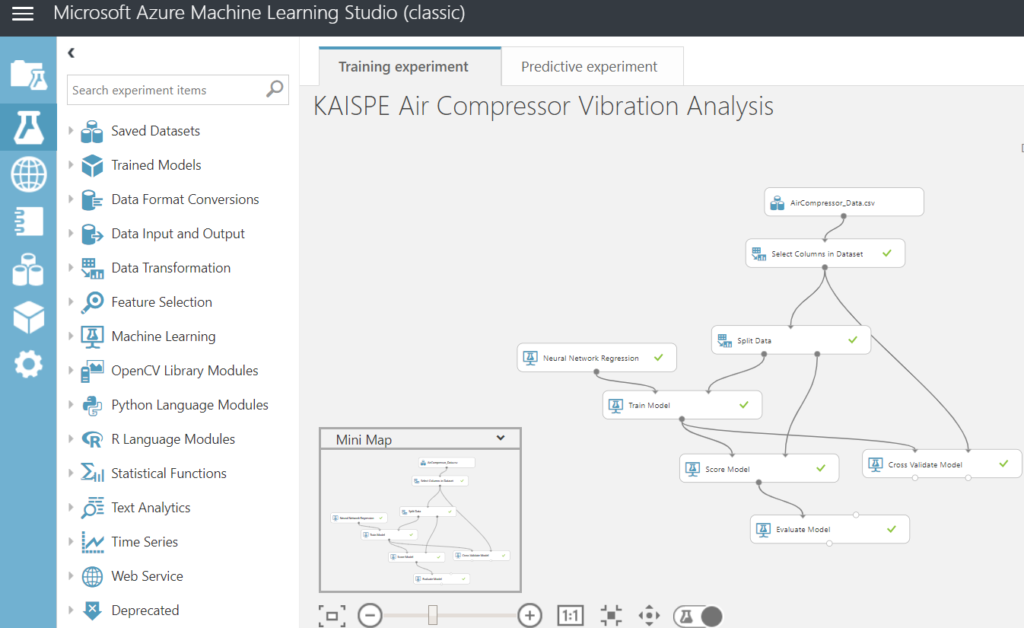

- Trained Models according to the need of the different types of data using Azure Machine Learning.

- Real-Time Data from Machines are going to the Azure IoT Hub.

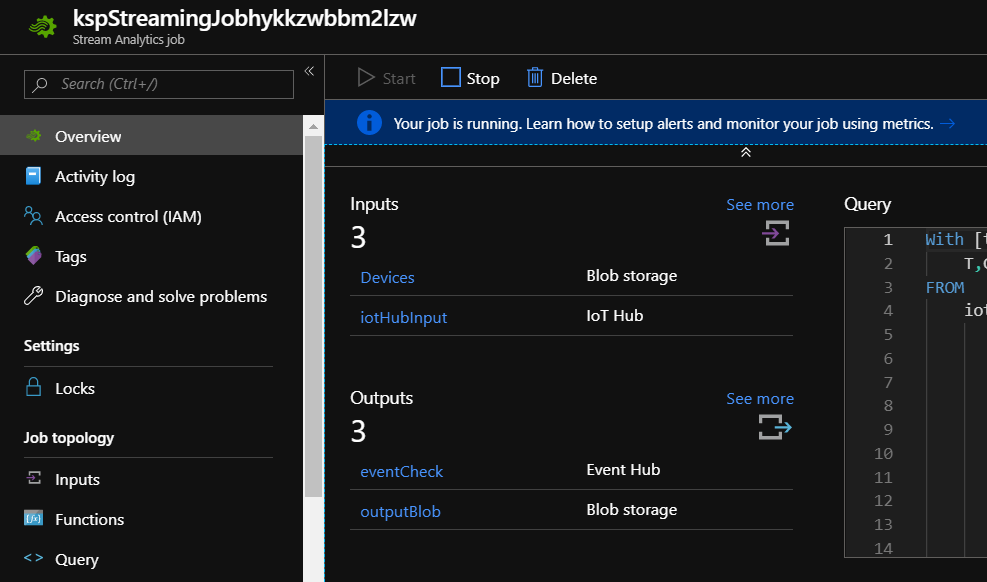

- Filter the Real-Time Data according to the user requirement using Stream Analytics.

- We Consumed Azure Machine Learning Trained Model according to the user environment.

- Finally, we have a comparison analysis between Real-Time Data and Our Trained Model Data and gives you the future operational Performance using KAISPE IoT Web Portal.

Now, we are going to demonstrate how KAISPE helps Air Compressor Industry to achieve Predictive Maintenance Feature.

We trained our model using Different Air Compressors Datasets.

Now we consumed Trained Model Web Service API for the Real-Time Prediction.

Now there are different types of Air Compressors that send different types of data to the Azure IoT Hub.

We have a target feature which is Vibration Analysis so we will extract the label features that’s are:

Pressure, Angular Speed and Piston Speed in our Azure Machine Learning Model.

We filtered Real-Time data according to the above features using Azure Stream Analytics.

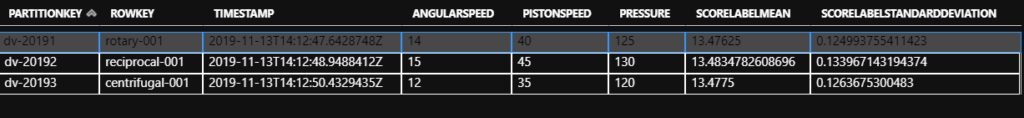

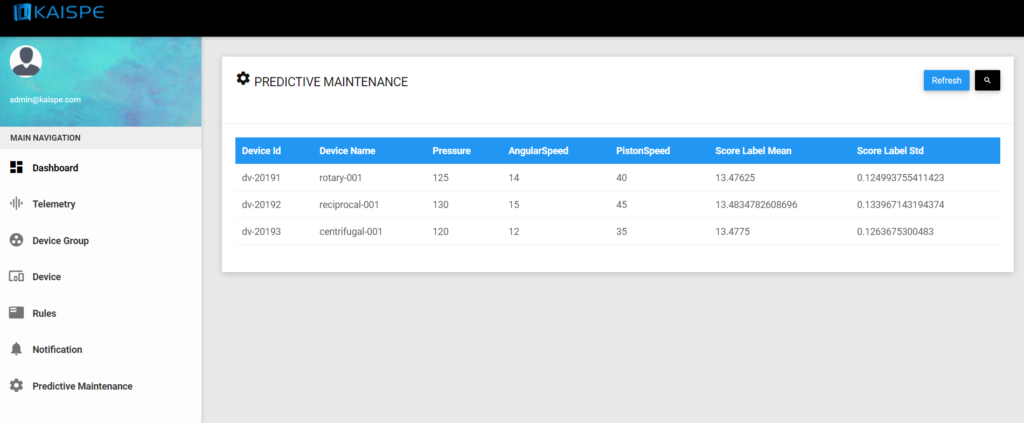

We have a comparison analysis between Real-Time Data and our Trained Model API to make the Prediction for the Air Compressor Vibration Analysis and stored the relevant device information and Prediction Values in the Azure Storage and shows in the KAISPE IoT Web Portal and gives advance notice of the possibility of the failure in Real-Time.

Azure Table Storage that stores Comparison Analyses between Real-Time and Trained Model.

KAISPE IoT Web Portal that helps you to Visualize Real-Time Prediction for the Possibility of the Future Failure.

I hope you liked this blog post. Keep in touch with us at [email protected]