Construction projects live or die by what happens on the job site. From early-stage site surveys to ongoing safety and quality inspections, accurate and timely site data is critical for keeping projects compliant, on schedule, and within budget.

Yet, for many construction companies across commercial, industrial, and infrastructure projects, site survey and inspection processes remain surprisingly outdated.

In this blog, we explore the most common pain points in construction site survey and inspection—and why addressing them is no longer optional.

1. Manual and Paper-Based Inspection Processes

Despite the scale and complexity of modern construction projects, many site inspections still rely on paper forms, spreadsheets, or unstructured notes. Inspectors record findings manually, take photos separately, and later re-enter data into office systems—often days after the inspection occurred.

Why this is a problem:

High risk of errors and missing information

Delayed reporting and decision-making

Increased administrative workload for field and office teams

Manual processes slow down projects and introduce avoidable risks at every stage of construction.

2. Lack of Real-Time Visibility Across Job Sites

Construction firms often manage multiple active sites simultaneously, but inspection data rarely flows in real time. Project managers, safety heads, and leadership teams frequently operate with outdated or incomplete information, learning about issues only after they have escalated.

The impact:

Safety hazards go unaddressed for too long

Quality defects are discovered late

Corrective actions are reactive instead of proactive

Without real-time visibility, managing construction risk becomes guesswork.

3. Inconsistent Inspection Standards and Practices

Inspection quality often depends on who is performing the inspection rather than on standardized processes.

Different inspectors may:

Use different checklists

Interpret safety or quality criteria differently

Document issues inconsistently

The result:

Non-uniform compliance across sites

Difficulty enforcing best practices

Increased exposure to regulatory penalties

Consistency is essential for scale—and manual methods simply don’t support it.

4. Compliance and Audit Documentation Gaps

Construction projects are subject to strict safety, quality, and regulatory requirements. Audits often demand:

Time-stamped inspection records

Photographic evidence

Inspector sign-offs and corrective action history

When documentation is scattered across files, emails, and devices, producing a complete audit trail becomes painful and risky.

Consequences include:

Audit delays or failures

Legal and contractual disputes

Loss of credibility with clients and regulators

5. Delayed Issue Resolution and Poor Follow-Up

Identifying an issue during an inspection is only the first step. In many projects, there is no structured way to:

Assign corrective actions

Track closure status

Verify resolution

Issues are followed up through informal channels like emails or phone calls, which are easy to miss or forget.

This leads to:

Rework and repeated defects

Extended project timelines

Increased costs

6. Limited Use of Visual Evidence

Photos and videos are critical for validating inspection findings—but they are often stored separately from inspection records. Without proper linkage between findings and visual evidence:

Accountability becomes unclear

Disputes are harder to resolve

Historical data loses value

Visual documentation should strengthen inspections, not complicate them.

7. Poor Coordination Between Field and Office Teams

Field inspectors, site engineers, safety officers, and office teams often work in silos. Inspection data doesn’t flow seamlessly into project management, safety, or quality systems, resulting in:

Slow communication

Delayed approvals

Reduced productivity

Effective site inspection requires connected workflows, not fragmented ones.

Why Modernizing Site Survey and Inspection Is Critical

As construction projects grow more complex and margins tighten, relying on manual and disconnected inspection processes is no longer sustainable. Modern, digital inspection approaches help construction companies:

Improve safety and quality outcomes

Ensure regulatory compliance

Gain real-time visibility across sites

Reduce rework, delays, and costs

Most importantly, they enable teams to shift from reactive problem-solving to proactive risk management.

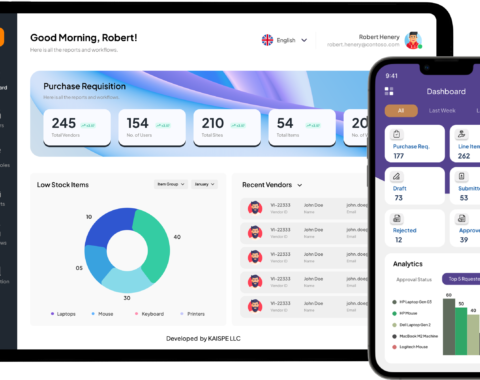

Site survey and inspection may not always be the most visible part of a construction project—but they are among the most critical. Organizations that modernize these processes gain a significant advantage in safety, efficiency, and project control by using KAISPE Field Service app specially designed for Construction industry. Those that don’t risk falling behind in an industry where precision, speed, and compliance matter more than ever. Contact us today info@kaispe.com to book a demo or take a test drive by visiting the product page.