Steel distribution has never been simple. But today, it is structurally more complex than ever.

Margin pressures, volatile raw material pricing, ESG compliance demands, traceability requirements, and unpredictable supply chains are exposing a critical weakness across the industry:

Traditional supplier relationship management models no longer work.

Digital transformation is no longer about ERP upgrades. It’s about re-engineering supplier collaboration.

And that starts with a Vendor Portal.

The Steel Distribution Reality: Where SRM Breaks Down

Steel distributors operate in a high-volume, price-sensitive environment where:

A few days of delay can disrupt downstream customers

Mill Test Certificates (MTCs) must be traceable and audit-ready

Supplier lead times fluctuate with market conditions

Contract renegotiations happen frequently due to price volatility

Yet most supplier management processes still rely on:

Email-based RFQs

Spreadsheet-based performance tracking

Manual onboarding documentation

Disconnected contract records

This fragmentation creates operational blind spots.

The 5 Structural SRM Gaps in Steel Distribution

- Communication Chaos

- Slow & Risky Vendor Onboarding

- Lack of Performance Transparency

- Limited PO & Shipment Visibility

- Compliance & Audit Exposure

The Strategic Shift: From Transactional SRM to Collaborative SRM

Forward-looking steel distributors are moving toward centralized digital vendor portals that:

- Standardize onboarding workflows

- Enable structured supplier communication

- Provide real-time PO visibility

- Track supplier performance KPIs

- Maintain compliance documentation in a single source of truth

This shift transforms suppliers from transactional vendors into performance-managed partners.

How KAISPE Vendor Portal Enables Modern SRM

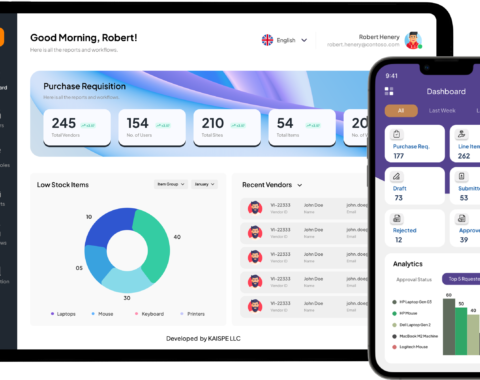

The KAISPE Vendor Portal (vp.kaispe.com) is purpose-built to digitize supplier collaboration workflows.

Here’s how it addresses steel-specific challenges:

- Centralized Collaboration Hub

- Automated Vendor Onboarding

- Supplier Performance Scorecards

- PO & Shipment Transparency

- Digital Audit Trail

Why This Matters Now

Steel distribution is entering a phase where:

- Price volatility is the norm, not the exception

- Customers demand faster fulfillment

- ESG reporting requirements are tightening

- Supply chain disruptions are recurring

Companies that continue managing suppliers through email and spreadsheets will face:

- Higher operational risk

- Lower supplier accountability

- Increased compliance exposure

- Slower reaction to market shift

The Leadership Question

The real question for steel distribution executives is not:

“Should we implement a vendor portal?”

It is:

“How much operational risk are we willing to carry without one?”

Organizations that digitize supplier collaboration today will gain:

- Better cost control

- Faster procurement cycles

- Stronger supplier accountability

- Improved working capital performance

- Higher resilience in volatile markets

In a margin-sensitive industry like steel distribution, those advantages compound quickly.